Category : Hardware News, News by T-Pole | cooling | 8 October 2024

In recent times, our customers are increasingly requesting liquid-cooled systems. The main reasons are the following:

- Ensure a robust, fan-free system. This need comes mainly from the mission-critical sector, in particular from the railway sector.

- Manage multi-GPU vision applications. Liquid cooling, in fact, proves to be extremely effective, allowing stable and safe operating temperatures to be maintained.

At TPole, we have gained significant experience in both the design and qualification of solutions of this type. In particular, we ensure the reliability of the system from both a mechanical and thermal point of view.

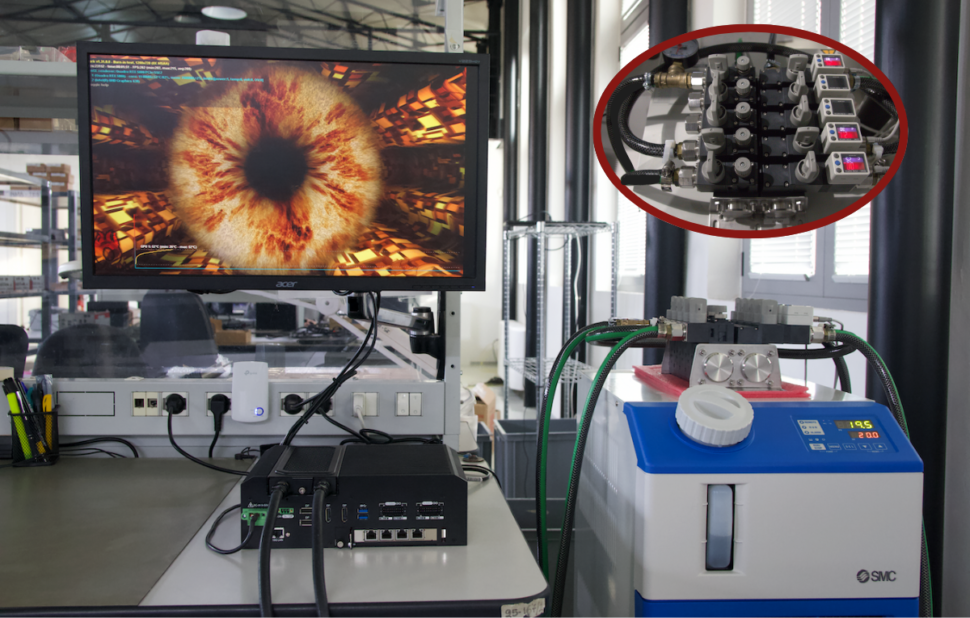

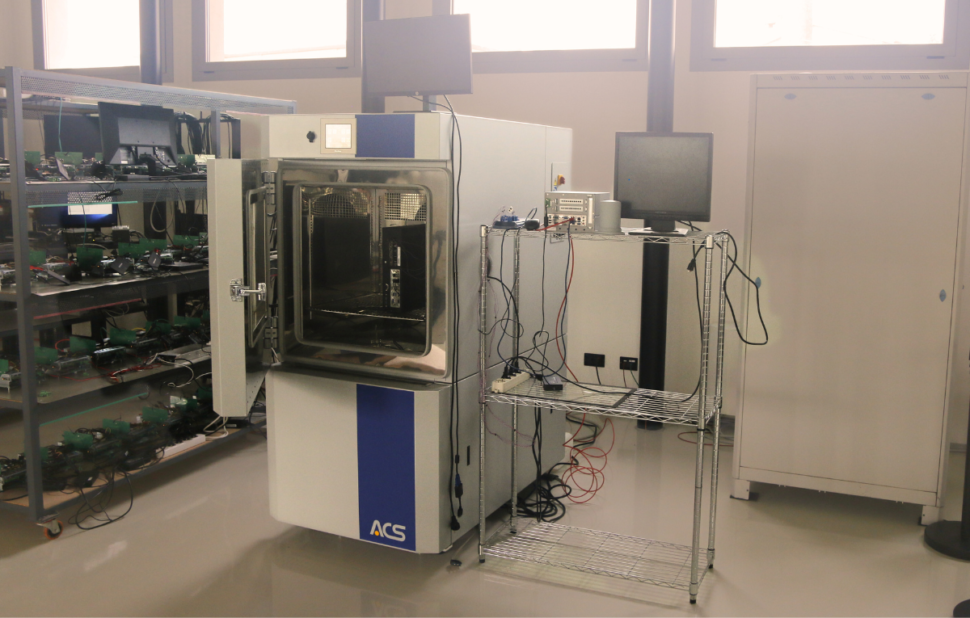

To validate these solutions, in addition to our climatic chamber, we have invested in a professional chiller, used to test and certify the proposals.

2 Liquid Cooling Solutions

Below we present some of the solutions created for our customers. One of these is completely liquid cooled, while in the other liquid cooling has been applied exclusively to the two GPUs.

1 – Vecow fanless PC

The first solution is a fanless PC provided by Vecow, based on a tenth generation architecture and equipped with an MXM module.

This PC has been qualified within the operating range requested by the customer -10°C ÷ 50°C. Product qualification, as required, was performed:

- With the customer’s application installed, to ensure that the work cycle reflects the real one in the field.

- In a climatic chamber, within the operating temperature range requested by the customer

All the data collected was extremely positive and delivered to the client in the form of a detailed report.

2 – 19″ Rack Mount GPUs

The second solution concerns the liquid cooling of two GPUs mounted on a 19″ rack.

Thanks to this solution, the liquid heatsink of the cards was much more compact than the standard one: each GPU occupied only one PCIe slot, leaving the customer space for further peripheral cards.

Additionally, system noise has been significantly reduced, ensuring extremely stable GPU operating temperatures.

The qualification of the system was particularly complex: we first validated the tightness of the liquid cooling system and all its components, carrying out accurate tests through the regulation of the chiller.

Subsequently, the system was tested at a temperature of 50°C, and the results obtained, as anticipated, were very satisfactory.

At TPole, we have developed in-depth know-how on this type of solutions. Customer choices can vary considerably based on different needs: mechanical robustness, thermal efficiency, silence and energy saving and in order to be able to respect them we can create completely custom systems.

We also have all the necessary equipment to qualify the solutions and guarantee a reliable product in the field.

Contact us for more information.